How to Choose the Right Industrial Air Conditioning System for Your Business

Choosing the right industrial air conditioning system is a crucial decision for businesses aiming to maintain optimal working environments and increase operational efficiency. According to a report by the U.S. Department of Energy, proper climate control systems can reduce energy consumption by 20-50%, emphasizing the importance of selecting the right configuration to meet specific needs. Industrial air conditioning systems are not only essential for temperature regulation but also play a vital role in maintaining air quality, which can significantly impact employee productivity and overall workplace health.

With the industrial sector continuously evolving, businesses face challenges related to varying cooling demands, fluctuating energy costs, and the need for increasingly sustainable operations. A survey conducted by the International Energy Agency found that industrial facilities account for nearly 30% of global energy consumption, underscoring the importance of energy-efficient air conditioning solutions. As businesses seek to combat rising energy costs and improve their carbon footprint, understanding the various types of industrial air conditioning systems available becomes paramount for ensuring both performance and cost-effectiveness. As we explore the key factors in selecting the appropriate industrial air conditioning system, a well-informed choice can lead to long-term benefits for both the environment and the bottom line.

Understanding Your Business's Cooling Needs

When selecting the right industrial air conditioning system for your business, understanding your cooling needs is paramount. Each business has unique requirements based on its size, layout, and operational activities. For instance, a manufacturing facility may generate significant heat due to machinery, necessitating a more robust cooling system compared to an office environment. Conducting a thorough assessment of your space—considering factors such as the square footage, number of employees, and equipment heat load—will help you determine the required cooling capacity.

Additionally, the nature of your business operations influences cooling demands. Businesses that handle sensitive materials or data, such as pharmaceuticals or information technology firms, often need systems that maintain strict temperature controls. Seasonal variations and peak usage times should also be considered, ensuring that your chosen system can efficiently handle fluctuating loads. By defining these parameters, you can make informed decisions that enhance comfort, improve productivity, and optimize energy efficiency in your industrial setting.

Evaluating Different Types of Industrial Air Conditioning Systems

When evaluating different types of industrial air conditioning systems for your business, several key factors must be considered to ensure optimal performance and efficiency. The main types of systems include centralized systems, packaged systems, and ductless mini-split systems. Centralized systems, often favored for larger facilities, can efficiently cool extensive areas and are typically more energy-efficient at scale. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), centralized systems can achieve energy savings of up to 30% compared to less efficient alternatives when properly maintained.

On the other hand, packaged systems provide an all-in-one solution that is ideal for smaller or mid-sized businesses. These systems come pre-assembled and include all necessary components, making installation simpler and reducing the need for extensive ductwork. A study by the U.S. Department of Energy indicates that packaged systems can be 10-20% more energy-efficient than traditional split systems, especially in commercial settings with significant cooling demands. Ductless mini-split systems, while generally best suited for spaces that require custom zoning, can also offer significant energy savings. They are less invasive during installation and can provide precise temperature control, which is essential for environments with varying cooling needs.

Ultimately, the choice of system should align with your specific business requirements, typically informed by factors such as the size of your facility, energy efficiency goals, and the nature of your operations. Consulting with a professional air conditioning technician can provide valuable insights and recommendations tailored to your particular situation, ensuring you make the most informed decision for your industrial cooling needs.

Evaluating Different Types of Industrial Air Conditioning Systems

This chart illustrates the efficiency ratings of various industrial air conditioning systems, helping businesses make informed decisions when selecting a system that best meets their needs.

Key Factors to Consider When Selecting an Air Conditioning System

When selecting an industrial air conditioning system, there are several key factors that businesses should take into account. One of the most important considerations is the size of the space that needs to be cooled. According to the U.S. Department of Energy, one ton of air conditioning can effectively cool approximately 400 to 600 square feet of space. Therefore, accurately calculating the square footage of your facility will help in determining the appropriate system capacity. Oversized systems can lead to increased energy costs and reduced dehumidification, while undersized units may struggle to maintain desired temperatures.

Energy efficiency is another critical factor. The Seasonal Energy Efficiency Ratio (SEER) is a rating that measures cooling output divided by energy consumption over a typical cooling season. Systems with a higher SEER rating indicate better energy efficiency. The U.S. Energy Information Administration reports that businesses that invest in energy-efficient systems can reduce their cooling costs by up to 30 percent. Additionally, evaluating the system's impact on indoor air quality is essential, as poor air quality can affect employee productivity and health. Research from the World Health Organization indicates that maintaining optimal indoor conditions can lead to improved performance and reduced absenteeism. By carefully considering capacity, energy efficiency, and air quality, businesses can select an air conditioning system that meets their needs effectively and sustainably.

How to Choose the Right Industrial Air Conditioning System for Your Business

| Factor | Description | Importance Level |

|---|---|---|

| Cooling Capacity | Determines the volume of air that can be cooled per hour. Must be sized correctly for the space. | High |

| Energy Efficiency | Measured by SEER or EER ratings. Higher ratings mean lower energy costs and environmental impact. | High |

| Installation Costs | Includes both equipment purchase and labor costs. Should fit budget constraints while meeting needs. | Medium |

| Brand Reputation | Consider brands known for reliability and quality. Research customer reviews and warranty conditions. | Medium |

| Maintenance Requirements | Some systems require more upkeep than others. Assess long-term maintenance costs and schedules. | Medium |

| Control Options | Look for systems with smart controls for better monitoring and efficiency. | Low |

| Noise Level | Assess how quiet the system operates, especially for work environments where noise is a concern. | Low |

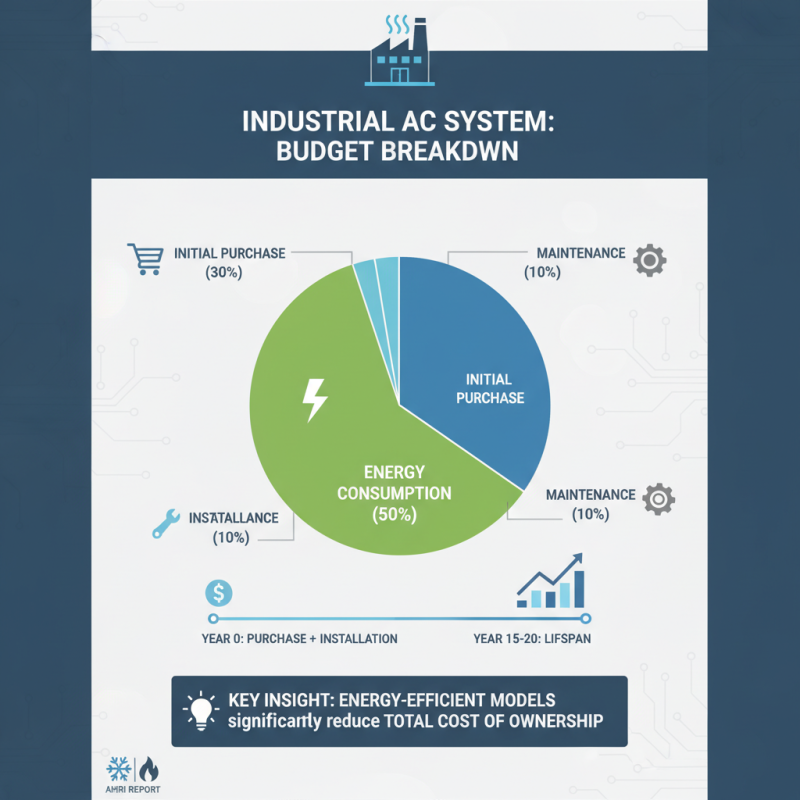

Budgeting and Cost Analysis for Industrial Air Conditioning

When selecting the appropriate industrial air conditioning system, understanding the budget implications is crucial. According to a recent report by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), the total cost of ownership for an industrial air conditioning system includes not only the initial purchase price but also installation, maintenance, and energy consumption over time. For instance, the average lifespan of a commercial HVAC system is approximately 15-20 years, during which the energy costs can account for up to 50% of the total expenditure, underscoring the importance of energy-efficient models.

Cost analysis also involves assessing the installation expenses, which can vary significantly based on system complexity and facility requirements. Research indicates that installation costs can vary between $3,000 to over $15,000 depending on the size of the unit and the specific needs of the facility. Additionally, ongoing maintenance is another essential factor, with estimates suggesting that businesses should allocate 5–10% of the system's initial cost annually for upkeep. This holistic approach to budgeting ensures that businesses not only invest wisely initially but also sustain their operational efficiency long-term, ultimately enhancing productivity while minimizing unexpected financial burdens.

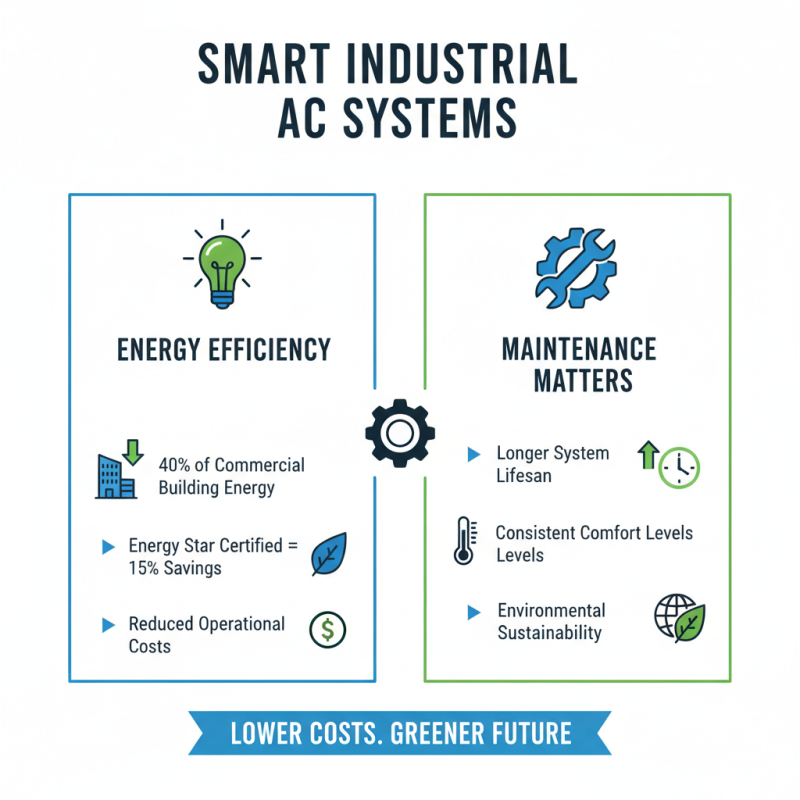

Maintenance and Energy Efficiency in Air Conditioning Systems

When selecting an industrial air conditioning system, maintenance and energy efficiency are critical factors that can significantly impact operational costs and environmental sustainability. According to the U.S. Department of Energy, heating, ventilation, and air conditioning (HVAC) systems account for about 40% of energy consumption in commercial buildings. Therefore, investing in energy-efficient air conditioning units can lead to substantial savings. For instance, systems that meet the Energy Star standards can reduce energy usage by up to 15%, contributing to lower operating costs while also enhancing comfort levels within the workplace.

Routine maintenance is essential to ensure optimal performance and longevity of air conditioning systems. The North American Technician Excellence (NATE) reports that regular maintenance can improve efficiency by as much as 20%. Tasks such as cleaning filters, checking refrigerant levels, and inspecting ductwork can prevent common issues that lead to costly repairs and reduced efficiency. Additionally, implementing a maintenance plan can extend the system's lifespan, with some systems operating effectively for 15 years or more with proper care. Hence, businesses must prioritize maintenance as an integral part of their air conditioning strategy to maximize energy efficiency and reduce long-term costs.

Related Posts

-

Ultimate Guide to Efficient Air Conditioning Installation for Your Home Comfort

-

Understanding the Benefits of an Air Conditioning Box for Energy Efficiency

-

10 Essential Tips for Choosing the Best Home Air Conditioning Systems in 2023

-

What is a Home Air Conditioning System and How Does It Work

-

Top 10 Air Conditioning Systems to Beat the Heat in 2023

-

Top 5 Air Conditioning and Installation Tips for a Cool Home This Summer